T8-T10A hot rolled steel round bars

T8-T10A hot rolled steel round bars

hiddenValue

- Product Detail

- | Technical Information

- | Packaging

-

- Commodity name: T8-T10A hot rolled steel round bars

T8, T10 and T12 are carbon tool steels. They are very hard. The Brinell hardness in annealed state is more than 300.Manual saw blade is T12 material, just quenching, hardness is greater.10 and 20 are low carbon, high quality structural steel, very soft, Brinell hardness is less than 155.Therefore, the fitter saw, laborious, the saw is very easy to wear.

T8-T10A hot rolled steel round bars information

Tool steels are high quality steels developed with controlled chemical composition to form properties essential for working and shaping of other materials. They are normally delivered to the suppliers in the soft annealed condition, which makes it easy for the manufacturer to machine the material with cutting tool for different applications.AISI T8 tool steel is a tungsten-cobalt-vanadium high-speed tool steel. The following datasheet will provide an overview of grade T8 tool steels.

Chemical and Mechanical

Chemical Composition

The chemical composition of T8 tool steels is outlined in the following table.

Element Content (%) Tungsten, W 13.25-14.75 Cobalt, Co 4.25-5.75 Chromium, Cr 3.75-4.5 Vanadium, V 1.80-2.40 Carbon, C 0.75-0.85 Molybdenum, Mo 0.4-1 Nickel, Ni 0.3 Copper, Cu 0.25 Manganese, Mn 0.2-0.4 Silicon, Si 0.2-0.4 Phosphorus, P 0.03 Sulfur, S 0.03 Physical Properties

The following table shows the physical properties of T8 tool steels.

Properties Metric Imperial Density 8.43 g/cm3 0.267 lb/in3 Mechanical Properties

The mechanical properties of T8 tool steels are displayed in the following table.

Properties Metric Imperial Tensile strength 1158 MPa 167.95 ksi Elongation 15% 15% Modulus of elasticity 190-210 GPa 27557- 30457 ksi Poisson’s ratio 0.27-0.3 0.27-0.3 Thermal Properties

The thermal properties of T8 tool steels are given in the following table

Properties Metric Imperial Thermal expansion co-efficient 16-17 µm/m°C 8.8-9.4 µin/in°F Thermal conductivity 16 W/mK 110 BTU.in/hrft².°F

T8 Range of productsProduct type Products Dimension Processes Deliver Status Plates / Sheets Plates / Sheets 0.08-200mm(T)*W*L Forging, hot rolling and cold rolling Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting Steel Bar Round Bar, Flat Bar, Square Bar Φ8-1200mm*L Forging, hot rolling and cold rolling, Cast Black, Rough Turning, Shot Blasting, Coil / Strip Steel Coil /Steel Strip 0.03-16.0x1200mm Cold-Rolled & Hot-Rolled Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting Pipes / Tubes Seamless Pipes/Tubes, Welded Pipes/Tubes OD:6-219mm x WT:0.5-20.0mm Hot extrusion, Cold Drawn, Welded Annealed, Solution and Aging, Q+T, ACID-WASHED

Cross Reference Table(Equivalent GradeGrade Standard Country Application T8 ASTM USA High-Speed Tool Steel -

Packaging

The company's products are packaged and labeled according to regulations and customer requirements. Take care to avoid any damage that may occur during storage or transportation. In addition, clear labels are attached outside the package to facilitate identification of product ID and quality information.

1. Wooden case packing, PVC packing, etc.2. Standard seaworthy packing machine customized

3. Port any port in China

In order to better ensure the safety of your goods, we will provide professional, environmentally friendly, convenient and efficient packaging services.

Stainless steel pipes are often packed and transported in bags, boxes or protective containers. Stainless steel conduits with an outer diameter greater than 6 inches can be transported in bulk, packed or not. The length, outer diameter, wall thickness, finish and transportation method determine the optimal packaging method. Most polishing tubes are packed in wooden cases or boxes made of other suitable materials.

It is necessary to bundle stainless steel pipes, because excessive quantities of stainless steel pipes during transportation may lead to risks such as bending, extrusion deformation or twisting of pipes during transportation. In addition, some other auxiliary measures need to be taken during baling. Flat steel wire belt is generally used for binding, but other suitable materials can also be used. The number of fixed knots depends on the length and weight of the bale.

-

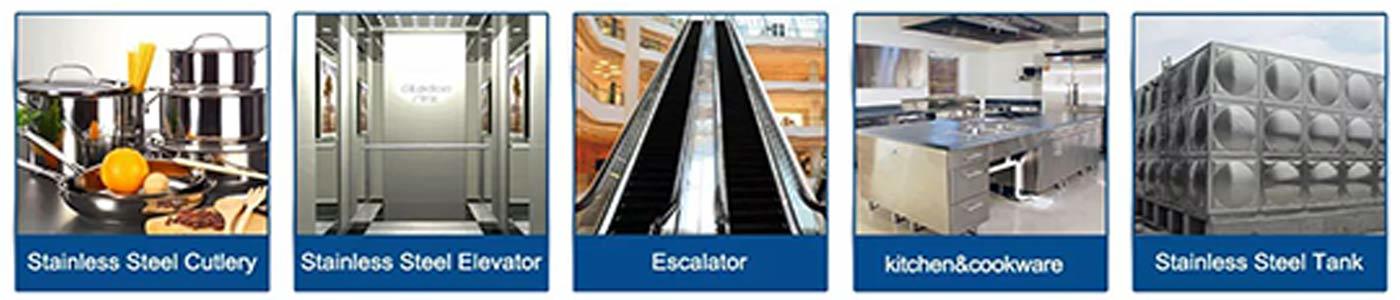

Application

1 Building Materials industry

2 light industry

3 Shipbuilding Industry

4 Mechanical Manufacturing

5 Bridge Construction

6 Energy Engineering

7 Water Conservancy Projects

8 Chemical Industry1. Automobile industry

Stainless steel plate not only has high corrosion resistance, but also has light weight, which is very important in automobile manufacturing. A large number of stainless steel plates are required for the manufacturing of automobile shells, and many international famous cars are now beginning to use stainless steel plates as the structural materials of automobiles. Even in high-speed railway, subway and other aspects, stainless steel plate is also widely used.

2. Water storage and transportation

Water has high requirements on the environment during storage. Stainless steel plate can effectively ensure the water quality is not polluted when used for water storage. Stainless steel plate is also recognized as a safe, hygienic and efficient water storage material in the world. Stainless steel plate will also be an indispensable material for water storage equipment in the future.

3. Construction industry

In fact, stainless steel plates were first used in the construction industry, and then gradually introduced into more fields. Decorative panels on the exterior walls of buildings are generally made of stainless steel plates, which are durable and beautiful.

In a word, stainless steel plates are widely used. In addition to the above, stainless steel plates can also be seen in the household appliance manufacturing industry. I hope you can have a more comprehensive understanding of stainless steel plate after reading this article. More wonderful content, remember to pay attention to TISCO stainless steel!

Products & Service

Related Products

Get a Free Quote

To: Tianjin Bohai Metal Company