410 410S Stainless Steel Coil

410 410S Stainless Steel Coil

hiddenValue

- Product Detail

- | Technical Information

- | Packaging

-

- Commodity name: 410 410S Stainless Steel Coil

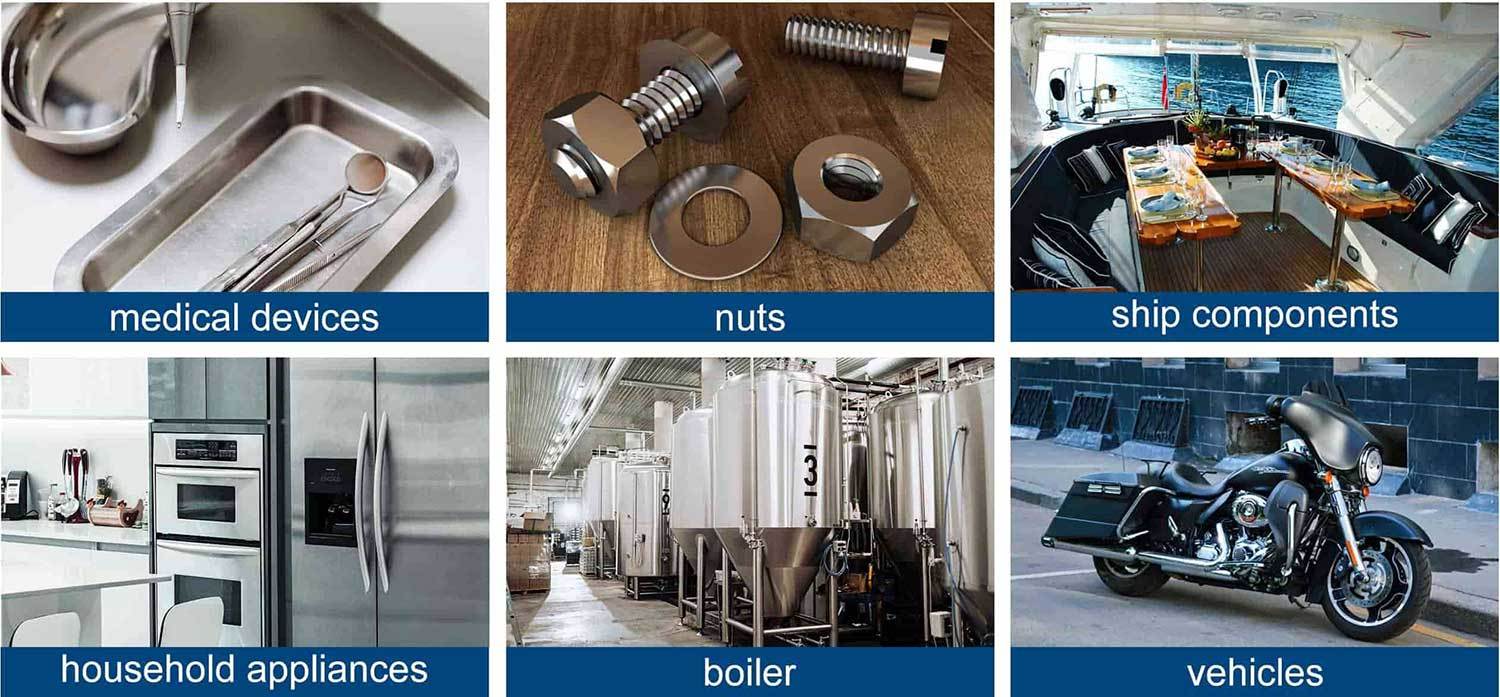

Characteristics of 410 410S Stainless Steel Coil: 1) High strength; 2) Excellent machinability 3) Hardening after heat treatment; 4) Magnetic; 5) Not suitable for harsh corrosive environment. 3. Scope of application General blade, mechanical parts, class 1 tableware (spoon, fork, knife, etc.).

410 410S Stainless Steel Coil Strip Specifications:

Grades

Stainless Steel J1, J2, J4, 201, 202, 301, 304, 304H, 304L , 309, 309S, 310, 310S, 316, 316L, 316TI, 321, 321H, 347, 409, 410, 410S, 420, 430, 441, 904L

Thickness

0.2mm - 60mm

Width

3.2mm - 2000mm

Length

AS PER CUSTOMER'S REQUIREMENT

Type of Material

STAINLESS STEEL SOFT, DEEP DRAW, EXTRA DEEP DRAW, QUARTER HARD, HALF HARD,FULL HARD.

Finish

NO.1, 2B, 2D, 2H, 2R, No.4, HAIRLINE, SCOTCH BRITE, SATIN FINISH, NO.8, BA.

Standard

ASME, ASTM, AISI, EN, BS, GB, DIN, JIS, SUS, etc.

manufacture

Cold Rolled ,hot rolled

Application

Decoration,Industry,food processing and medical industry ,ships building industry etc.

Certification

SGS, BV, IQI, TUV, ISO, CE, etc

Coil Weight

3-10 Tons Or As Your Requirements

Tolerance

±1%

MOQ

1 ton

Supply Ability

5000 tons / month

Lead Time

7-15 working days after the receipt of 30% deposit

Payment Terms

30%T/T Advance + 70% Balance

Price Terms

FOB, CFR, CIF, EXW

Packing

Standard sea-worthy package or as required

Chemical Composition of 410 410S Stainless Steel Coil:

GradeC

Si

Mn

P

S

Ni

Cr

Mo

201

≤0 .15

≤0 .75

5. 5-7. 5

≤0.06

≤ 0.03

3.5 -5.5

16.0 -18.0

-

202

≤0 .15

≤L.0

7.5-10.0

≤0.06

≤ 0.03

4.0-6.0

17.0-19.0

-

301

≤0 .15

≤L.0

≤2.0

≤0.045

≤ 0.03

6.0-8.0

16.0-18.0

-

302

≤0 .15

≤1.0

≤2.0

≤0.035

≤ 0.03

8.0-10.0

17.0-19.0

-

304

≤0 .0.08

≤1.0

≤2.0

≤0.045

≤ 0.03

8.0-10.5

18.0-20.0

-

304L

≤0.03

≤1.0

≤2.0

≤0.035

≤ 0.03

9.0-13.0

18.0-20.0

-

309S

≤0.08

≤1.0

≤2.0

≤0.045

≤ 0.03

12.0-15.0

22.0-24.0

-

310S

≤0.08

≤1.5

≤2.0

≤0.035

≤ 0.03

19.0-22.0

24.0-26.0

316

≤0.08

≤1.0

≤2.0

≤0.045

≤ 0.03

10.0-14.0

16.0-18.0

2.0-3.0

316L

≤0 .03

≤1.0

≤2.0

≤0.045

≤ 0.03

12.0 -15.0

16 .0 -1 8.0

2.0 -3.0

321

≤ 0 .08

≤1.0

≤2.0

≤0.035

≤ 0.03

9.0 - 13 .0

17.0 -1 9.0

-

630

≤ 0 .07

≤1.0

≤1.0

≤0.035

≤ 0.03

3.0-5.0

15.5-17.5

-

631

≤0.09

≤1.0

≤1.0

≤0.030

≤0.035

6.50-7.75

16.0-18.0

-

904L

≤ 2 .0

≤0.045

≤1.0

≤0.035

-

23.0·28.0

19.0-23.0

4.0-5.0

2205

≤0.03

≤1.0

≤2.0

≤0.030

≤0.02

4.5-6.5

22.0-23.0

3.0-3.5

2507

≤0.03

≤0.8

≤1.2

≤0.035

≤0.02

6.0-8.0

24.0-26.0

3.0-5.0

2520

≤0.08

≤1.5

≤2.0

≤0.045

≤ 0.03

0.19 -0. 22

0. 24 -0 . 26

-

410

≤0.15

≤1.0

≤1.0

≤0.035

≤ 0.03

-

11.5-13.5

-

430

≤0.1 2

≤0.75

≤1.0

≤ 0.040

≤ 0.03

≤0.60

16.0 -18.0

-

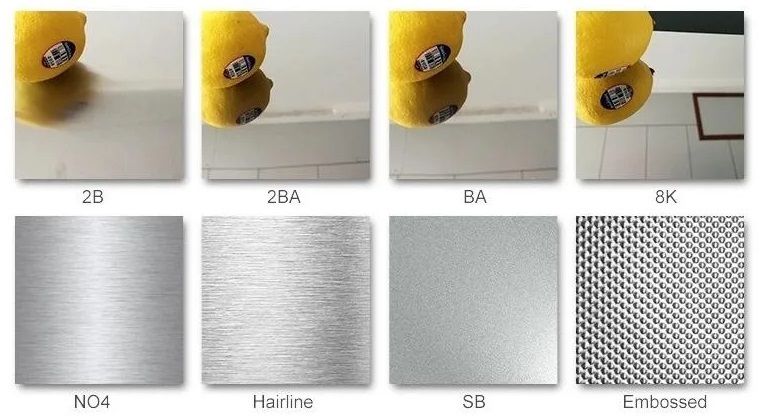

Stainless Steel Surface:

Stainless steel has a variety of surfaces, please contact us for confirmation.

Surface Finish

Definition

Application

2B

Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster.

Medical equipment, Food industry, Construction material, Kitchen utensils.

BA

Those processed with bright heat treatment after cold rolling.

Kitchen utensils, Electric equipment, Building construction.

NO.3

Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001.

Kitchen utensils, Building construction.

NO.4

Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001.

Kitchen utensils, Building construction, Medical equipment.

HL

Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size.

Building Construction.

NO.1

The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling.

Chemical tank, pipe.

-

Packaging

The company's products are packaged and labeled according to regulations and customer requirements. Take care to avoid any damage that may occur during storage or transportation. In addition, clear labels are attached outside the package to facilitate identification of product ID and quality information.

1. Wooden case packing, PVC packing, etc.2. Standard seaworthy packing machine customized

3. Port any port in China

In order to better ensure the safety of your goods, we will provide professional, environmentally friendly, convenient and efficient packaging services.

Stainless steel pipes are often packed and transported in bags, boxes or protective containers. Stainless steel conduits with an outer diameter greater than 6 inches can be transported in bulk, packed or not. The length, outer diameter, wall thickness, finish and transportation method determine the optimal packaging method. Most polishing tubes are packed in wooden cases or boxes made of other suitable materials.

It is necessary to bundle stainless steel pipes, because excessive quantities of stainless steel pipes during transportation may lead to risks such as bending, extrusion deformation or twisting of pipes during transportation. In addition, some other auxiliary measures need to be taken during baling. Flat steel wire belt is generally used for binding, but other suitable materials can also be used. The number of fixed knots depends on the length and weight of the bale.

Products & Service

Related Products

Get a Free Quote

To: Tianjin Bohai Metal Company